Description

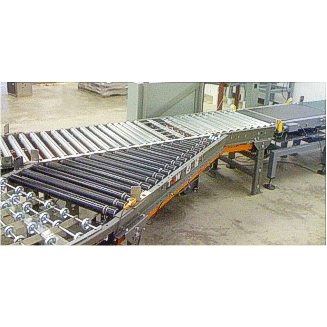

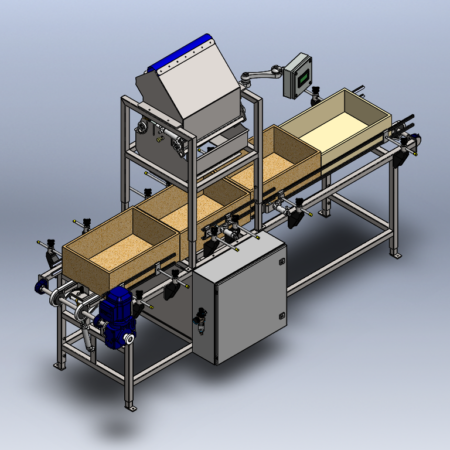

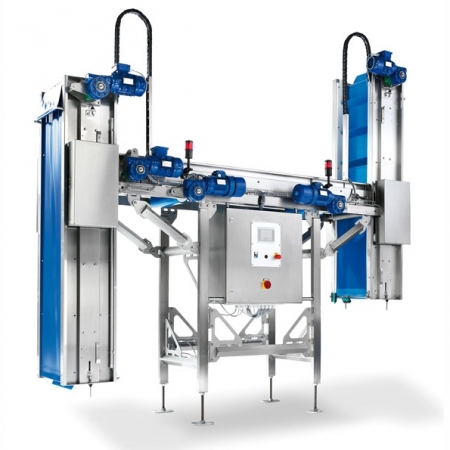

Ag-Pak’s Box Check Weighing System with pacing conveyor properly spaces boxes for accurate weighing. The system Automatically removes out of tolerance boxes or RPC’s (returnable plastic containers) by sending a reject signal to a powered “Pop-up” drive wheel diverter to smoothly direct the out of tolerance boxes onto the reject lane.

The parallel reject lane merges onto a gravity skate wheel conveyor that allows the operator to easily move the box onto a Trim Scale for correcting the fill of the box to the proper weight. After adding or removing product to achieve the proper weight, the operator can easily position the box back onto the production line from the Ball Transfer bed that is fitted to the Trim Scale.

A digital readout clearly shows the weight and the “Legal for Trade” Weight Indicator can be fitted with an optional color coded light tree for visual target weights. Red shows underweight, green is good or target weight; and yellow indicates an overweight situation based on the parameters entered into the controller.

Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018