Description

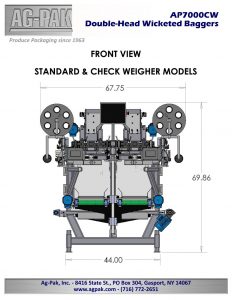

Ag-Pak’s AP7000CW Wicket Bagger with Check Weighers is Fast, Reliable, Easy to Operate, and Easy to Maintain.

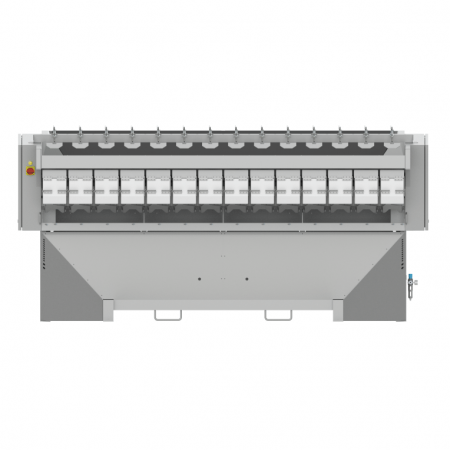

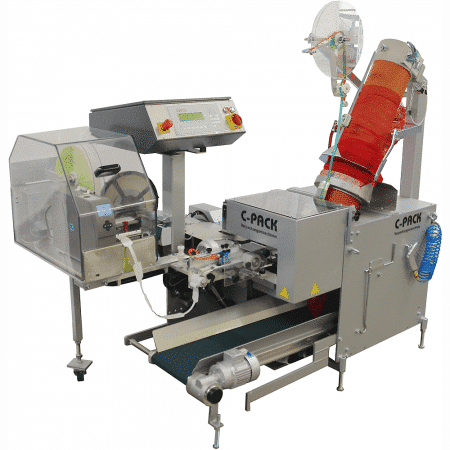

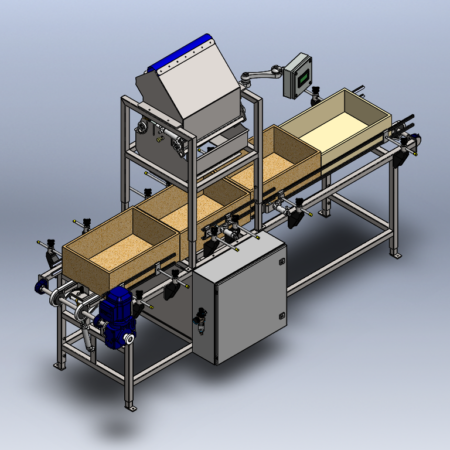

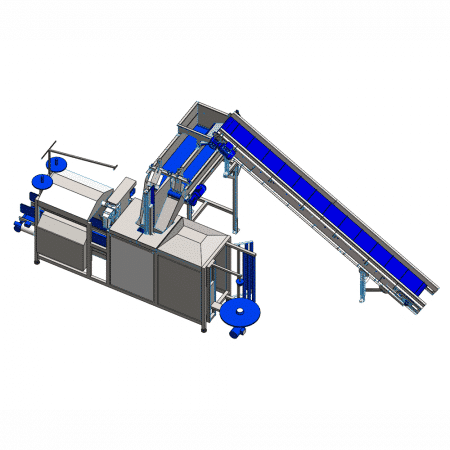

Twin bagger heads are fed from two collectors. The filled bags are closed by standard Kwik Lok closers. Closed bags are passed immediately to the check weighers. There is one check weigher for each bagging head. No singulation is required for check-weighing. From the check weighers, bags are transferred to a rear outfeed cross conveyor that can convey bags to either side. Bags that do not meet the weight specifications are automatically diverted from the rear conveyor. Easy to use touch screen controls are standard on both models.

Features and Benefits

Fast

Capable of 50 bags per minute with 5lb bags including check-weighing. (Actual rates depend on application.)

Reliable

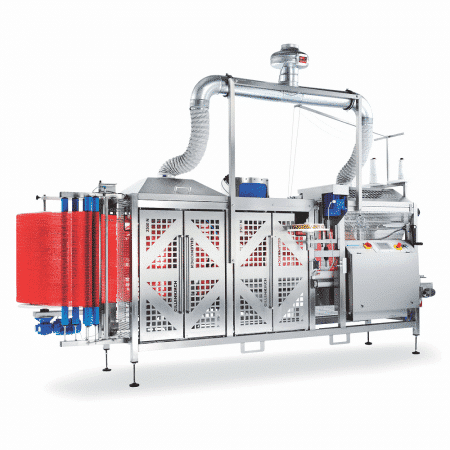

Stainless steel contact surfaces, powder coated frame, high quality components, and proven electronics ensure minimal down time.

Touch Screen User Interface

Easy operation through quick access to menus and recipes. Includes integrated parts drawings with exploded views for part identification.

Easy Adjustability

Both horizontal and vertical wicket pin adjustments to accommodate different bag sizes and manufacturers – Tool-less, quick bag change-over

Compact Design

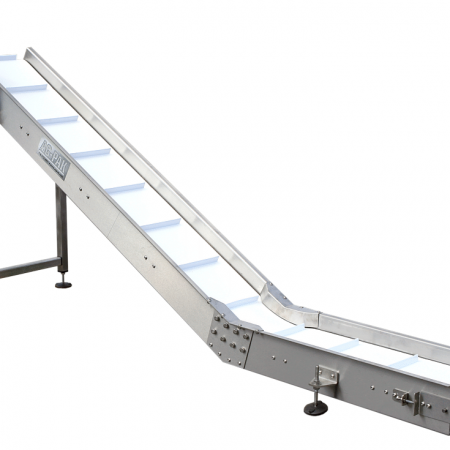

Minimizes footprint. Check weigher model designed to fit extended frame under scale.

Bridge Detecting Photo Eyes

Help ensure even product flow and reduce operator involvement

Innovative Vane Block and Inline Vacuum Generator

Reliable and quiet bag opening

UL Listed Electrical Cabinet

Built in-house by our UL-certified electricians

Easy to Maintain

Heavy duty closure swing arms allow easy access to closure devices – Convenient control cabinet location – Readily available commercial components

Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018 Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018

2020 Ag-Pak

2020 Ag-Pak

Ag-Pak, Inc. 2018

Ag-Pak, Inc. 2018